CORE CENTER

Home >> Products >> CORE CENTER

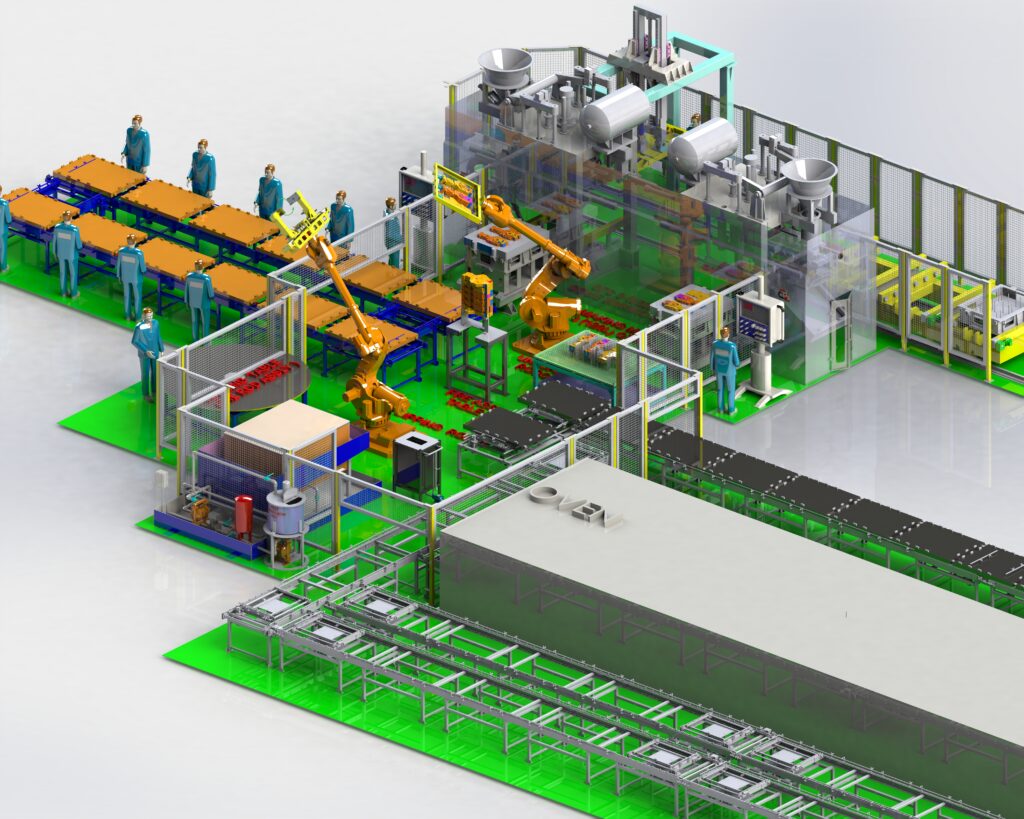

ARKORA made Core Center is designed, integrated and manufactured as per customization for producing critical cores in one setup required for mass production.

KEY FEATURES

- Machine capacity 120 ltr. HPL (Horizontal Parting Line) – 2 nos.

- Robot capacity 500 kg. – 2 nos.

- Robust, effective and reliable design

- Continuous clamping and no core box movement during the entire blow and cure cycle

- Quick tool change system with hydraulic operation

- Special coating in hopper, sand cartridge and blowing head, to avoid sand adhesion on the walls

- Advanced blow system with lower blow pressure to avoid wear & tear of core box tooling

- Automatic lubrication system

- Operator panel at the side of the machine

- Lower and upper core ejection system

- The machine is designed so that the core box remains stationary and solidly clamped under high pressure

- throughout the complete core making cycle

BENEFITS

- High productivity

- High quality core

- Less dependability on manual labor

- Automation in core manufacturing and assembly process

- Core making machines are provided with common triple core box changing station

- Less tool change time

- Single line process flow to ensure consistent output.